When it comes to pipe protection, it’s important to understand what types of technology are available to you. From OCTG pipe protection to pipe end protectors, there are plenty of ways to get the job done. Let’s review a few of the most popular technologies being used to protect pipes from corrosion.

Cathodic Pipe Protection

Cathodic protection can be a highly effective way to reduce the risk of corrosion. This method of protection utilizes an electrical current to effectively neutralize corrosion. Cathodic protection is a common form of pipe protection that is used in underground environments or underwater environments. If performed on a brand new pipeline, it’s possible for cathodic protection to prevent corrosion entirely.

Coatings and Linings

If you’re looking for an easy way to protect pipes, then coatings and linings are going to be the best route. Coatings and linings can be used on pipes both above ground and below ground, which makes them a practical choice for almost any pipe protection application. Some of the most common materials used for this application include zinc, epoxy, and urethane. In order for protection to be foolproof, every coating and lining must be applied and cured without error.

Pipe Chocks

When it comes time to transport pipes or utilize pipe storage, tools like pipe chocks are going to be an excellent form of protection. Pipe chocks might not seem like advanced technology, but sometimes a simple tool is all you need to keep your piping safe. Pipe chocks are used to prevent pipes from shifting during storage and transit. When your pipes reach their destination, they’ll be unscathed.

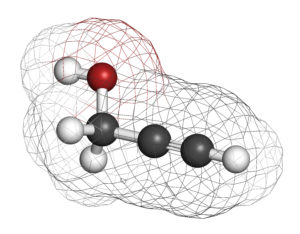

Corrosion Inhibitors

For corrosion protection, inhibitors can make a big difference. Corrosion inhibitors are compounds that are added to pipelines in order to prevent corrosion. These compounds can be added as a thin layer within the pipeline. This method is popular because of its cost-effectiveness. One small step can help prevent leaks, spills, and corrosion within pipes.

Pipe protection is key to any operation. The important thing to remember is that there are plenty of ways to keep your pipes safe during operation, storage, and transport.

Whether you are looking for cathodic pipe protectors, various coatings and linings, corrosion inhibitors, or MSI’s quality pipe chocks, manufactured and ready to be shipped right to your front door, make sure that pipes are protected!