MSI is always on the lookout for new and exciting innovations to the oil and gas industry. While controversial, fracking is an ongoing and important part to the industry as a whole. While current systems have been adapted over the years to comply with environmental, social, and corporate governance (ESG) to improve functionality, the system is far from perfect. The NOV Ideal Electric Frac (eFrac) fleet is attempting to provide great value to the operator while being environmentally and socially sensitive, as well.

What is Fracking and How Does It Work?

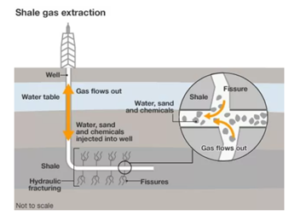

Once the steel casing is in place, a perforating gun is lowered into the wellbore and fired, releasing charges that are imperceptible on the surface but cause fractures in the rock layer. Once this has been done, the perforating gun is removed.

Next, fracking fluid is pumped into the well. This fluid is mostly water and with a mixture of chemicals that is pumped in at a high rate of pressure with a pumping tank. The fluid is forced into the gaps and fissures, causing the rock to crack or fracture, allowing the fracking fluid to come back up to the surface. The fluid is removed and taken to a treatment plant.

Once the fluid is removed the fractures will be kept open with the use of proppants, which are used to keep the cracks open. Once the fractures are propped open, the natural gasses can escape from the shale layers, allowing the gas to flow up from the fissures and into the well. The gas will be moved from the well into the storage tanks until it can be piped to the market. Many of these wells will stay in production for 20-40 years so this process will continue as long as the well is producing.

Fracking: An Ongoing, Labor Intensive Process

Providing a wide variety of pipe protection products to companies who utilize fracking methods, we know that it can be a very rugged process that is hard on drill pipe and downhole assets. Even with the best protective products and processes, fracking has continued to require a lot of work and the use of fuels to power the pumping process, impacting the overall profitability of the fracking process. This is precisely why MSI is excited to share the innovations of companies like NOV who are launching new products such as the NOV Ideal Electric Frac (eFrac) Fleet.

NOV Ideal Electric (eFrac) Fleet

Knowing that current systems have been both adapted to comply with ESG and exhausted all potential gains, NOV saw a need to make fracking more efficient. This is because conventional systems have had to work very hard, resulting in wear and tear on equipment and the increased fuel consumption. In the words of NOV product development manager Travis Bolt,

“Fracturing is a costly and mechanically intensive operation. We wanted to look for the next technology platform that our customers can build their business around, and the is a major step forward in reducing total cost of ownership and simplifying the fracturing process.”

To create a more efficient system, NOV applied their expertise in electric AC Rig Technology and forward-thinking engineered systems to develop an electric frac fleet that positions NOV as a leader in this emerging and exciting market. The Ideal eFrac system has been designed with ESG compliance in mind. When compared to traditional fracking systems, the eFracsystem reduces fuel costs by as much as 89% with wellhead natural gas-powered turbines and lowers C02 emissions by 74% compared to Tier 4 fleets that flare gas.

The NOV Ideal eFrac Fleet relies on electric equipment and simplified drive trains. The system has a much smaller footprint, featuring 5,000-hp, electric-driven pumps and fewer pump bores to service, further eliminating costs related to engines and transmissions. The reduced fleet size also translates to less equipment needing transport, resulting in up to 43% less roadway traffic and further reducing carbon emissions.

his system has effectively eliminated risks and complexities in all areas from electrical connections to rigging iron, producing an extremely organized and easy-to-understand system that doesn’t require extensive training for fracking crews. The fully remote-operated fracking fleet uses intelligent machine monitoring, centralizing knowledge to one location on the oil well pad, and removing personnel from hazardous environments.

MSI Wants to Be Your Source for Pipe Protection Products and Industry News

As a manufacturer and distributor of pipe protection products, we enjoy keeping up to date on industry news. Changes in the way the oil and gas industry operates impacts pipe protection and our clients.