Technology today is ever-improving. Continued technological improvement has impacted the oil industry greatly, with new improvements making drilling more efficient, effective and safer than ever before. With drilling taking place all around the world, new challenges are being discovered and overcome continually, often with the help of new technology. NOV recently launched the Falcon Reamer, a product that will improve the efficiency of drilling in the Middle East and North Africa (MENA) Market. MSI is excited about this new reamer as it goes hand in hand with our focus on protecting tubulars and tubular products.

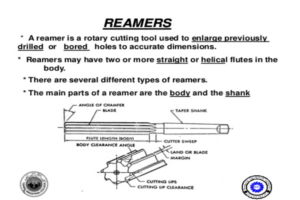

What is a Reamer?

A reamer is a tool that is used after drilling has taken place. Most often, a reamer is used to enlarge a wellbore. Reaming can be done for a wide variety of reasons and is often related to the condition of the landscape, although it can be done for maintenance purposes as well. Reaming is necessary when a hole was not able to be drilled large enough, often due to tough terrain such as those found in the Middle East and North Africa market. Reaming may also be practiced to maintain the hole size, as it is not uncommon for plastic formations from drilling to flow into the wellbore over time.

What is the Falcon™ Reamer?

The Falcon reamer tool is new and was developed specifically to address the challenging borehole conditioning needs in the MENA market. This next-generation reamer is built upon the success of the successful Dog Leg (DL) reamer borehole conditioning tool. The DL Reamer has established itself as a leader in the market, with the Falcon being a new and improved offering for the MENA region.

The Falcon is fitted with ReedHycalog polycrystalline diamond compact (PDC) cutters, creating the most efficient and cost-effective solution for MENA operators to overcome challenges in that market. The reamer is built to improve wellbore integrity, aids in tripping and running casing or production strings, improves weight transfer, and reduces torque and hole tortuosity in high angle and complex trajectory wells. Additionally, the Falcon features new boomerang-shaped blades and a large radius on the leading edge, increasing contact with the borehole area while also reducing torque. This design combined with the NOV-developed Multifunctional Advanced Placement Software (MAPS™) allows for ideal placement in the drill string and maximum tool efficiency not seen in other reamers.

What are the Features of the Falcon Reamer?

Like the pipe protection offerings by MSI, what sets the Falcon reamer apart from other reamers on the market is an impeccable design based on a clear understanding of what is needed from those utilizing these tools. The Falcon has some great features that set it apart from the competition such as:

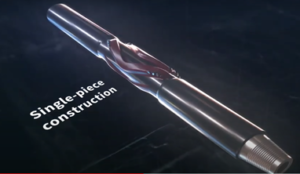

- One-piece construction. The Falcon is built from a single piece of steel that contains properties to match the connection tool requirements of operators. This one-piece design helps to ensure easing pairing with drill string components.

- Dual height and dual function blade design. Implementing active blades that are set higher than passive blades allows the tool to both condition and enlarge the wellbore, improving tool efficiency.

- Multifunctional Advanced Placement Software (MAPS). The Falcon uses the in-house developed software that allows the Falcon reamer to be placed in the bottom hole assembly where it is most effective with borehole conditioning. This accurate placement also ensures that there are no negative effects on the bending stresses or contact forces at any point in the interval.

- Low-torque cutting structure. The falcon reamer generates less than 5% of the reactive torque generated by the bit, resulting in reduced surface torque when compared to similar offset runs that do not utilize the Falcon reamer.

- Bi-directional cutting structures. This reamer enhanced cutting structures that ensure the tool is improving the wellbore when drilling ahead, as well as when the string is rotating in either direction.

- Maximized tool internal diameter. The Falcon minimizes pressure lost through the tool and allows fishing of most retrievable measurement-while-drilling (MWD) components.

- Re-engineered blade layout. The blade layout of this reamer offers maximum protection to the cutting structure during drill-out, increasing the efficiency of the blade when agitating cuttings on the low side of the wellbore in high-angle direction applications.

- Large selection of premium PDC cutters. The cutter type on the Falcon reamer can be optimized to suit the needs of each specific application.

The Falcon reamer has a lot of great features that make it the premier option for reaming in the MENA market. This reamer has been built to overcome the challenges of difficult terrain that is notorious for long drill times. Like other drill technology or pipe protection products, the Falcon offers a great return on investment because it will maximize efforts in the most efficient manner.

MSI: Helping to Educate and Protect

Here at MSI, we enjoy bringing you new information about developing technology that will maximize your efforts while also protecting your assets. We hope that you have found the Falcon reamer information interesting, as we are quite excited about this technology that is certain to make drilling in some of the toughest conditions much more efficient. We strongly believe when tools such as The Falcon reamer and our pipe protection products are combined that company assets will be well protected. We invite you to learn more about The Falcon reamer as well as our pipe protection products and how they can provide a new and exciting opportunity for you now and in the future.