Proper pipe handling is essential for ensuring workers’ safety and the pipes’ integrity. Accidents, injuries, and damage to equipment can occur if proper handling procedures are ignored. These practices can help mitigate risks and enhance operations.

Planning and Communication

Before beginning pipe handling operation, a well-defined plan is in place. This should include identifying the scope of work, assessing potential hazards, and determining the equipment and resources. Effective communication between team members is paramount to ensure everyone understands their roles and responsibilities. Clear instructions and safety guidelines should be communicated to prevent misunderstandings and minimize accidents.

Proper Training and Pipe Handling Equipment

Handling pipes requires specialized knowledge and skills. It is imperative to provide comprehensive training to workers on safe handling techniques, including proper pipe lifting, carrying, and maneuvering. Ensuring that all workers are adequately trained and certified to operate pipe handling equipment promotes safety, improves efficiency, and prevents damage.

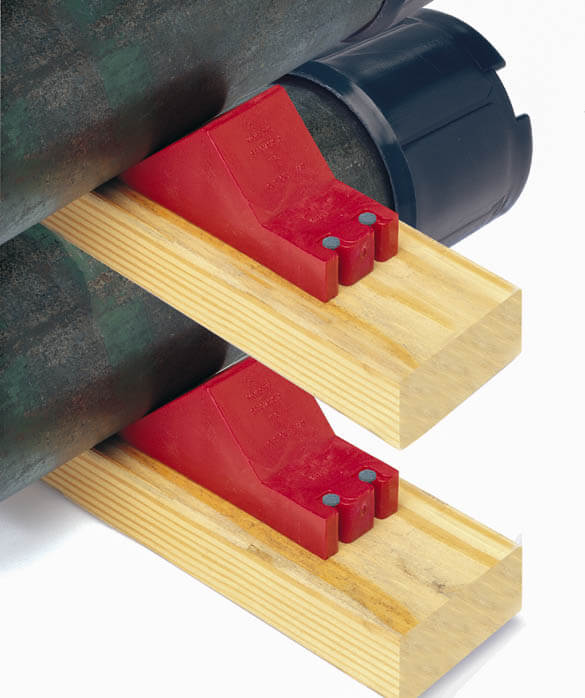

Thread protectors play a crucial role in ensuring safety, including providing secure connections, structural integrity, vibration resistance, and more. Stabbing guides enhance safety by facilitating the alignment and insertion of pipes during the stabbing process, providing alignment assistance, injury prevention, and protecting pipes from damage.

Inspection and Maintenance of Handling Equipment

Regular inspection and maintenance of handling equipment are critical. Inspect cranes, slings, and hooks for signs of wear, damage, or malfunction. Address issues and remove faulty equipment from service until repairs. Follow routine maintenance procedures to ensure equipment is in optimal working condition.

Proper Lifting Techniques

Adhering to proper lifting techniques is crucial to prevent back injuries and strains. Encouraging team members to lift heavy pipes together and using mechanical aids like hoists or cranes whenever possible can significantly reduce the strain on individuals and minimize the risk of injuries.

Use lifting bails to facilitate the lifting of pipes at rig sites to before making up. By providing a designated and secure attachment point, lifting bails help minimize the risk of load slippage, falling objects, or accidents during the lifting process. They contribute to a safer work environment by reducing the potential for damage to the lifted object, equipment, or injury to personnel.

Secure Stacking and Storage

Efficient storage and stacking practices are essential to prevent pipe damage and maintain an organized work environment. Pipes should be stacked in a stable manner, using appropriate supports or racks to prevent them from rolling or falling. Clear signage indicating the pipes’ size, type, and condition should be placed on each stack to facilitate easy identification and prevent accidents. Maintain adequate space between stacks to ensure safe access and minimize the risk of entrapment or falls.

Using pipe storage equipment creates a safer environment, protecting workers and pipes. Bumper rings prevent damage to the ends of pipes and ensure their integrity. Pipe chocks enhance safety by providing stability and controlling the movement or rolling of pipes. Use Raptor Pipe Packing Frames to increase safety. By providing a secure and stable structure for packing and transporting pipes, these packing frames reduce the risk of accidents, injuries, and damage. Lastly, Rhino Tubular Handling Systems increase safety by providing a reliable and efficient pipe storage and handling solution, reducing the risk of accidents, improving stability, and ensuring proper pipe organization.

Continuous Monitoring and Safety Culture

Maintaining a culture of safety is crucial for safe pipe handling. Regularly monitoring the work environment, identifying potential hazards, and addressing them promptly are important for preventing accidents. Encouraging workers to report safety concerns or near-miss incidents fosters a proactive approach to safety. Regular safety meetings, training refreshers, and recognition of safe practices reinforce the importance of safe and efficient pipe handling.

MSI is a Global Leader in Pipe Protection

Proper pipe handling safety is vital. By prioritizing safe and efficient pipe handling, companies can protect their workforce, minimize downtime, and optimize productivity in this critical industry. When you need the proper equipment and quality assistance, look no further than MSI Pipe Protection. We’re here to help when you need us most.