Those involved in the oil, gas, and drilling industries know how vital pipe thread protector products are. With how essential they are for rig operations, it’s easy to see how so many of these drill pipe protectors, amongst other pipe products, get tossed to landfills and improperly disposed of.

Ethical decision-making is becoming more and more of a priority across all industries, and the oil, gas, and drilling industries are not exempt. Learning how to correctly dispose of drill pipe protectors and thread protector caps is something that should be at the top of every oil company’s to-do list. Continue reading to learn more about how to ethically dispose of these items and how MSI Pipe Protection Technologies is helping these companies accomplish this more efficiently.

Plastic Waste and the Oil Industry

Some consider it especially important for those in the oil industry to be mindful of plastic waste. This is because of the contributions that oil companies make to the creation of plastic. People then look to oil companies to see the efforts that they are making individually to combat the harmful effects of pollution on the planet. If oil and drilling industry players are going to have a hand in producing plastic, they should emphasize moral ways of disposing of it.

Plastic is a material that many oil companies look to for high-quality product protection and it is used to ensure that operations run smoothly, so companies should be conscious of how much waste they are producing with these needed materials. But what are the plastic materials that oil companies are utilizing on a day-to-day basis and how can they be actively aware when getting rid of them?

What Are Pipe Protectors?

Pipe protectors are one item made from plastic that oil companies utilize. They are also one of the easiest to properly get rid of. Line pipe protectors are caps that are non-threaded. They are created to completely cover a pipe’s openings and keep them safe from both debris and damage to the pipe end.

If you are transporting water in your pipes, having pipe protectors is key. Much of the water being transported needs to remain clean. Should your pipes not be completely secured, you risk water being polluted with any number of things that make the water unfit for human consumption — rust, chemicals, odors, and more. For this reason, ensuring there is a pipe end protector on all of your pipes is not only a worthy investment but a necessary one.

In addition to offering the contents of your pipes safety, these large plastic pipe caps keep money in your wallet. Damaged pipes come with many costs — the cost to evaluate the problem, replace or repair the pipes, the cost of what was potentially contaminated within the pipes. Further, time is money, and the time needed to assess and replace pipes and parts takes away from the time that could be spent on different, more worthy tasks. Taking preventative action to cover the ends of your pipes with these plastic coverings now saves you big in the long run.

The MSI Pipe Protection Technologies Difference

The pipe protectors made by MSI Pipe Protection Technologies are effective and durable, but they come with other benefits, as well. They are exceptionally easy to install and remove from your pipes, saving you time and money. You can find them in closed-end designs, as well as both liftable and non-liftable designs. They work for believed pipes, as well as plain-end pipes.

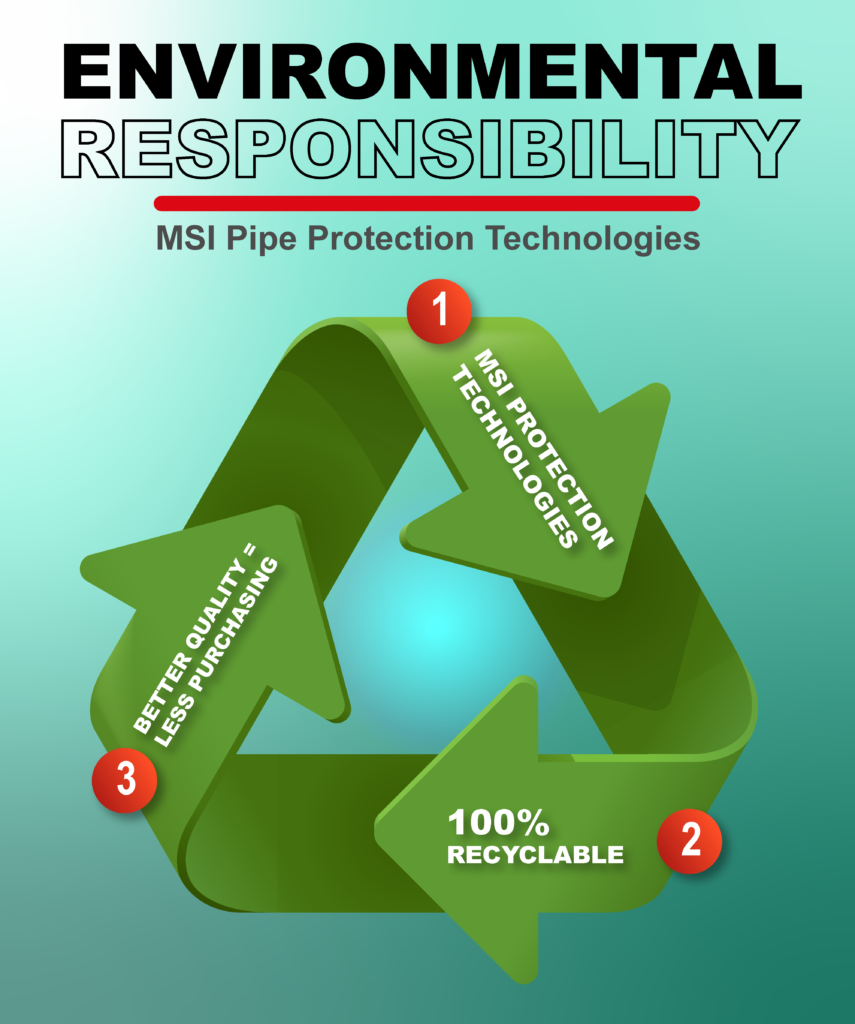

99.9% of our generated plastic waste is recycled back into the process to manufacture new protectors. This translates to around 90,000 lbs of plastic that gets recycled back into our manufacturing process.

Regarding the “how” – any plastic waste (i.e. swarf, purge, “bad” protectors) goes to our grinding room and gets ground into shards. We then mix the ground shards of plastic and mix with black colorant at a blending station. From there, it goes straight back to the injection molding process. We are able to mold new, black materials from generated in-house scrap waste.

At this time, we only do this with our in-house waste as it is a process we can control. If we were to collect additional protectors, you lose some control over the performance of the product as you don’t know that plastic’s prior life and the environmental conditions and chemical conditions that plastic was exposed to. With manufacturing everything in house, its history is known and engineered to manufacture properly. These new parts are also thoroughly tested as part of our comprehensive product testing.

This process is very different than say, selling reconditioned protectors in the field, which also shares the noble goal of waste elimination. I know C1 has written articles about that in the past so we should have them on our site.

Why Recycle Thread Protectors?

Much of the waste in pipe yards comes from thread protectors that are no longer needed. This leads companies using these products to question how to best get rid of them. As previously stated, companies using pipe protectors from MSI Pipe Protection Technologies have the option of recycling them. This smooth process provides companies with the chance to eliminate waste that would normally take up space at a landfill.

To do this, companies should seek out companies that specialize in recycling plastic. Those companies will then categorize the plastics into usable and unusable plastics and grind down the usable plastics into smaller pellets. Then, these pellets are used to produce a variety of other parts.

Why Not Reuse Pipe Protectors?

We at MSI Pipe Protection Technologies emphasize the recycling of pipe protectors, as opposed to the reusing of pipe protectors. According to Statista, the global demand for crude oil was projected to rise to approximately 96.5 million barrels in 2021. Having such a high demand can lead some companies to cut corners and reuse products. While reusing can be beneficial both for the environment and for companies in certain instances, pipe protectors are not the recommended product to do this with.

As discussed, the safety of the contents within your pipes is likely of incredibly high importance. Reusing thread protector caps lessens their effectiveness in the long term, resulting in the potential for the contents within your pipes to become contaminated. For this reason, purchasing previously used pipe protectors, or reusing them from your own company, is not the wisest decision.

Lengthening the Life of Your Threads

Investing in high-quality thread protector caps, as opposed to purchasing cheaper, used caps, can still have a positive impact on the environment. By buying high-grade products, you are ensuring that they last longer. When you use these items for longer lengths of time, you decrease the frequency in which you have to purchase more. Buying cheaper end caps that will only need to be replaced once they fail to do their job will eventually have a negative impact on both your finances and the environment.

We are happy to take the time to help you discover the needed steps to becoming a better friend to the environment. We can also assist you in learning how to best recycle our variety of high-quality products.