MSI is proud to offer a wide variety of pipe protection products that help protect tubular products to ensure they are always in the best working condition possible when they arrive on the job site. Not sure pipe protection products are something you need to invest in? Looking at how drill pipe is usually damaged can help understand pipe damage prevention with the right products and processes in place.

Drill Pipe Failure

Drill pipe failure is quite common and occurs for various reasons including but not limited to:

Drill Pipe Fatigue. Fatigue is usually seen as microcracks, macrocracks, and fractures in the drill string and pipe. These issues are usually caused by a combination of corrosion and cyclic stress.

Twist-off. Twist-off happens when the drill string breaks into two pieces. This is often a result of over-tightening or when high torque is encountered during extended-reach or directional drilling.

Parting. Excessive tensile stress will cause parting. Parting often occurs when an overpull is applied to compensate for sticking.

Burst or Collapse. Pipes will burst or collapse when excessive internal or external pressure is applied.

Unfortunately, it may not be possible to completely do away with drill pipe failure, although there are steps to take to manage stress on the tubular product including proper handling, storage, and inspection.

Cyclic Stress

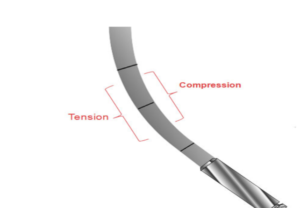

Cyclic stress often occurs in directional wells because the drill string is experiencing stretching and compression simultaneously. The drill string bends along the curvature of the well, so one side of the string experiences greater tension, and the other side experiences more significant compression. This process causes structural stress and will dramatically shorten the life expectancy of the drill pipe.

To reduce cyclic stress, operators should attempt to minimize the severity of any doglegs, providing a straighter path for the drill string. Trying to control drill string vibrations will also help eliminate structural stress that can exacerbate cyclic stress.

Corrosion

Corrosion can be caused by a wide variety of chemicals in the drill mud that interacts with the drill pipe. The most common culprits of decay include oxygen, carbon dioxide, and hydrogen sulfide. Salts and organic acid found in the mud can also cause corrosion. While it is challenging to eliminate corrosion due to the nature of the work, changing the chemical composition of drill pipe can help in conjunction with the use of corrosive scavengers to help control the mud pH levels, especially when hydrogen sulfide is present.

Pipe Sticking

“Sticking” or “pipe sticking” is when a pipe cannot be freed and pulled out of a hole without damage. There are two types of pipe sticking: differential pressure and mechanical.

Differential-pressure pipe sticking happens when some or all of the drill string gets embedded in the mud. Diluting or gasifying the mud weight with nitrogen to reduce the pressure can resolve this sticking.

Mechanical pipe sticking occurs when drilled cuttings from the annulus are not entirely removed or in the presence of borehole instabilities. Removal of the annulus is the first step in fixing mechanical pipe sticking.

Damaged Drill Pipe Threads

Drill pipe threads can become damaged in various ways, such as adverse drilling conditions, operator error, improper storage, or faulty manufacturing. Proper care, storage, use, and drill pipe inspection can help owners avoid thread damage. The consistent use of quality thread protection will ensure the threads are in good working condition. MSI is proud to offer an extensive selection of thread protectors, including standard sizes and custom offerings.

Borehole Instability

The term borehole instability refers to a hold that cannot maintain its shape, size, or structural integrity. A Variety of factors such as earth movement, water absorption, dispersion, overburden, or pore pressure can cause the instability of the borehole. Borehole instability can cause many problems such as a stuck pipe mentioned previously, bridge and fill up, difficulties logging, and the enlargement of the wellbore.

To reduce the risk of borehole instability, drilling operators are encouraged to use appropriate borehole fluid and hydraulics, determine the proper hole trajectory, choose the correct mud weight and spend as little time in the open hole as possible.

Over Torque

Over torque is one of the most common causes of thread damage. Utilizing too much torque will occur when the drill pipe is under torqued before it is run down the hole. When there is not enough torque going into the hole, it will continue to tighten as it goes down, causing it to be over-tightened. The most effective way to avoid over-torque is to ensure all connections are properly tightened to their usage specifications before use. This can require more planning, but determining optimum torque serves to minimize the risk of over-torque and damage to drill pipe threads.

Lost Circulation

Lost circulation is a term that describes the uncontrolled flow of drilling mud into a formation. Lost circulation happens when the pressure against the formation exceeds the total pressure of the formation. Lost circulation is widespread when large, coarse, and porous formations are naturally or easily fractured or depleted. Lost circulation is problematic because it can increase mud expense and subsurface blowouts.

In most instances, lost circulation can be avoided by maintaining proper mu weight, minimizing annular fracture losses, utilizing appropriate formation pressure and fracture gradients, and avoiding restrictions in the annular space.

MSI Products Assist in Pipe Protection

The drill pipe protection from MSI can help operators protect their pipe and drilling equipment. MSI offers a wide selection of drill pipe protection, storage, and handling products such as thread protectors, bumper rings, pipe chocks, and our RHINO tubular handling systems, etc. The MSI product line works to prevent issues such as thread damage, corrosion, and other pipe failures. When the tubular arrives at the project site, you can rest easy knowing it is in good working condition.