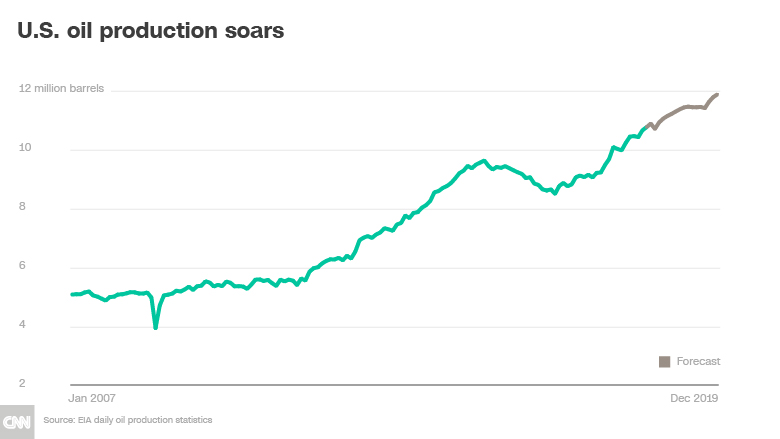

As global demand for oil and gas rises, producers must ramp up production while looking for new efficiencies in operations. Though the number of rigs in the US decreased over the last year, production continues to rise. And oil producers are finding new ways to extract higher volumes from existing wells. Lower CAPEX limits mean pumpers need to reuse and repurpose existing OCTG (Oil Country Tubular Goods) for completions on drilled but uncompleted (DUC) wells.

And with continued industry innovations, everyone benefits from the latest production boom by using horizontal drilling and hydraulic fracturing techniques. All the while, producers still hold a critical concern for ensuring the protection of their drilling and tubing equipment. This is why they turn only to trusted pipe protection products from reliable API standard-leading manufacturers.

CNN Source: EIA daily oil production statistics

Modern Pipe Protection for OCTG in Oilfield Operations

Producers will benefit from investing in pipe protection equipment and components in the long run. How so? The advanced increases in lifecycles for sucker rods, drill strings, perforating guns, and tubes make it possible. Additionally, using robust and reliable protection systems improve operational safety, reducing the risks of a Lost Time Incident (LTI) and production stoppages. The oil and gas industry remains one of the most dangerous working environments, therefore taking care of the OCTG during every step of the drilling, completion, and production cycles should be a priority for all producers.

OCTG Pipe and Thread Protection Systems

For threaded drill strings, thread protectors ensure the integrity of the joints and couplings during OCTG transport and storage. If pumpers don’t secure the threads, the sections that operate under torquing conditions may fail and lead to preventable downtimes. MSI’s range of thread protectors come in all API sizes, providing maximum protection against corrosion or damage during handling. We design thread protectors from heavy-duty plastic with precision-engineered CNC cut threads. As a result, this reduces failures and ensures reliable operations in the harshest environmental conditions.

Heavy-duty plastic thread protectors for either internal or external threads provide rugged impact protection for either short or long-term storage. The downhole equipment remains a significant investment for all producers. Therefore, utilizing the latest innovations in protection technology will preserve these investments and reduce overheads during every stage of the lifecycle. MSI can provide Premium or API standard solutions for all types of pipe threads, or manufacture custom sizes according to any niche requirements.

Tube & Pipe Stacking and Storage Solutions

Whenever tube and pipe sections require stacking for transport or storage, a rigid and solid frame or rack will protect both OCTG and staff. For convenient handling and safe loading or unloading, Tubular Handling Systems (THS) will prevent surface-to-surface contact and protect against corrosion. MSI provides stacking and storage solutions for drill pipes, tubes, and casings. Since OCTG are critical for production in the downhole, any undetected damage can lead to catastrophic failures in the well. To ensure safe and reliable operations, using a solution for heavy-duty bundling, transporting, and lifting of the sections will protect the pipes and tubes during every stage prior to installation.

MSI provides tubular handling systems that reduce the risk of racks collapsing and maintains the minimum distance between sections. With lifting eyes tested at four times the required weight, these solutions will ensure safe transport and storage of all OCTG to the site.

Similarly, pipe chocks and bumper rings help secure each section and enforce separation, stabilizing every pipe in its resting position. These are especially important during servicing operations, where teams need to pull strings or sections from the downhole. Ensuring every section remains free from damage or contact will increase the lifetime of the OCTG.

Handling and Downhole Protective Equipment

Handling downhole equipment requires additional safety devices to protect against damage and ensure the safety of workers. With MSI’s stabbing guides and lifting bails, pumpers can easily manage every step of the process. The stabbing guides have steel cores and urethane outer shells, including handles for complete control during make-up activities.

For tool joints, stabilizers, drill pipe, collars, bits, and subs, lifting bails securely fit into the ends, allowing for efficient handling and movement of the OCTG. Manufactured according to API thread connection standards, MSI’s lifting bails also comply with ASTM A27 Grade 60-30. We load test all lifting bails up to three times the safe working load. This ensures they can operate under strenuous conditions continuously. With unique serial numbers, all history from manufacturing to use is traceable. Furthermore, MSI provides standard API sizes, or we can produce any custom designs as required.

Protecting OCTG Investments with Innovative Pipe Protection and Handling Equipment

MSI Pipe Protection Technologies has the most extensive range of OCTG protective devices. For enhanced safety and reduced damage, we provide every kind of protective device an oil producer or upstream tubular manufacturer needs. With an ISO-certified manufacturing process, every component complies with a quality standard that ensures they operate reliably for the entire lifecycle. As producers face downward pressure from market influencers, maintaining key investments during well completions and servicing operations will reduce the overheads and prevent untimely production stoppages.

Though our MSI headquarters is in Houston, we can provide pipe protection equipment anywhere on the globe. With the world’s energy consumption rises, producers must leverage existing infrastructure to continue increasing yields from new or existing wells. MSI has helped customers achieve greater efficiencies and secure their OCTG for longer lifecycles and improved overall performance.

Offshore Energy: 10 Key Ways Operations Have Been Strengthened

For top-quality protective products that help improve operations and enhance safety solutions during drilling operations and well completions, request a quote. You may also call MSI Pipe Protection Technologies directly for immediate assistance at 877-276-9208.