MSI is always on the lookout for new products and services that can work in conjunction with our pipe protection products. NOV has recently launched their sour service drill stem product line that when paired with MSI’s product offering, can help oil and gas companies protect their pipe even in the most rugged regions of the world.

What is Sour Service?

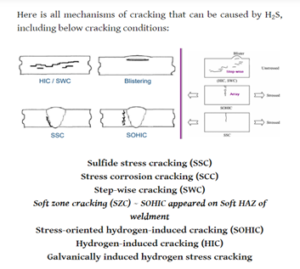

Sour service is the term used to refer to the exploration and production environments in oil and gas that have enough hydrogen sulfide to cause the cracking of metallic materials. Sour service is one of the biggest challenges experienced by the oil and gas industry due to the risk to assets and operations. Sour service failures are reported around the world when operators attempt to use general pipe grades due to sulfide stress cracking, which often leads to catastrophic failure. These widespread failures have shown that the use of specialty pipe grades in these conditions is essential.

MSI Provides Solutions for Sour Service

The challenges of sour service render standard forms of pipe protection useless. NOV understands the pain of risking assets for sour service and the challenges that come with it such as equipment availability, the proper balance between strength and SSC resistance, a variety of OEM grades and standards, and more. To help relieve the pain points of those in sour service, NOV has simplified the selection process and has developed a smaller range of products to help drilling become as safe and as efficient as possible.

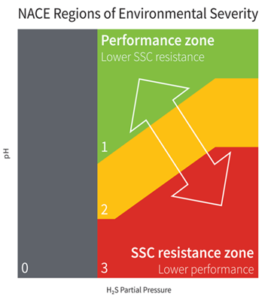

This new offering maximizes performance in every region of the NACE environmental severity diagram and is packaged to make product selection as simple as possible, choosing from six H2Shield grades for drill pipe and three for heavyweight drill pipe. These grades for drill pipe will offer as much performance as the driller needs to safely and efficiently complete their work.

H2Shield™ Grades

Engineered Sour Service Grade Drill Pipe

The H2Shield grades maximize tension and torque in all three regions of the NACE MR0175-2015 diagram of environmental severity. The region 1 and 2 grades

Customized Sour Service Grade Drill Pipe

CYX™ is a family of grades that allows the end-user to customize drill pipe by adjusting a variety of parameters. This is well suited to operators who understand the balance between the need for strength and SCC resistance. This works best in long-term development projects in well-known fields. This customized option allows for multiple meaningful variations on the pipe strength (105-125 ksi), on tool joints (110 to 130 ksi) and options of prequalified or NACE tested components.

Sour Service Grades for Heavy Weight Drill Pipe

H2Shield Heavy Weight Drill Pipe (HWDP) grades are also available for standard and spiral projects. These are designed with strength in mind, as they utilize tubes that are stronger in tension than the drill pipe with tool joints of similar strength to maximize the MUT of connections. These HWDP are offered in three grades to match the drill pipe environmental severity regions of the NACE Diagram. XD 90 HWDP offers the strongest tensile capacity as a region three product.

IRP and Other Industry Sour Service Grade for Drill Pipe and Heavy Weight Drill Pipe

IRP SS Grades have been integrated into the NOV range of H2Shield products for region 3. These products are specifically designed and manufactured to meet the Canadian industry-related practice requirements. A special alloymaterial and advanced heat treatment processes are used to maximize SSC resistance for the highly concentrated H2S environments of region 3.

Pairing MSI Pipe Protection Products with NOV Sour Service Products

NOV is solving many of the issues of sour service with their new grades of products that are for specific regions of the world. MSI’s pipe protection products can be beautifully paired with these new offerings for sour service. Our products work to protect all assets during transportation, storage, and use. Drill Pipe protection products that should be considered include our Guardian Drill Pipe Protectors but other helpful products may include:

Pipe protection considerations are essential in all drilling environments, especially those known to be challenging to assets and operations, such as sour service.

MSI Wants to Be Your Pipe Protection Resource

With this new product line being offered by NOV to assist with the pains of sour service, now is the time to think about how you protect all of your assets. Pipe protection is essential for all types of drilling because when pipe is damaged the whole operation can be shut down. Not sure what products would best suit your needs? We would be happy to help! You can browse our catalog to learn more about our offerings, or you can contact us. We are looking forward to working with you to protect your assets and continue to bring you new product information that will benefit your overall operation.