Many factors impact innovation in the pipe protection industry

Science and technology are constantly pushing the limits of humanity’s energy production capabilities. Better understanding allows operators to improve how they manufacture, transport, store, and install piping systems. Pipe protection has also undergone similar innovations that continue to evolve with the energy industry’s changing needs. Advances in environmental sciences further highlight the subtle differences in corrosive reactions in OCTG and the associated metallurgical components.

In fact, extraction applications continue to benefit from advancements in knowledge and improvements in manufacturing through the pipe protection industry. Operators must naturally consider each well’s integrity and the total installed lifecycle of pipelines. Consequently, this is a critical part of the design, construction, and completion activities for new projects.

Increased Consumption Requires New Production Efficiencies

https://www.eia.gov/todayinenergy/detail.php?id=29672

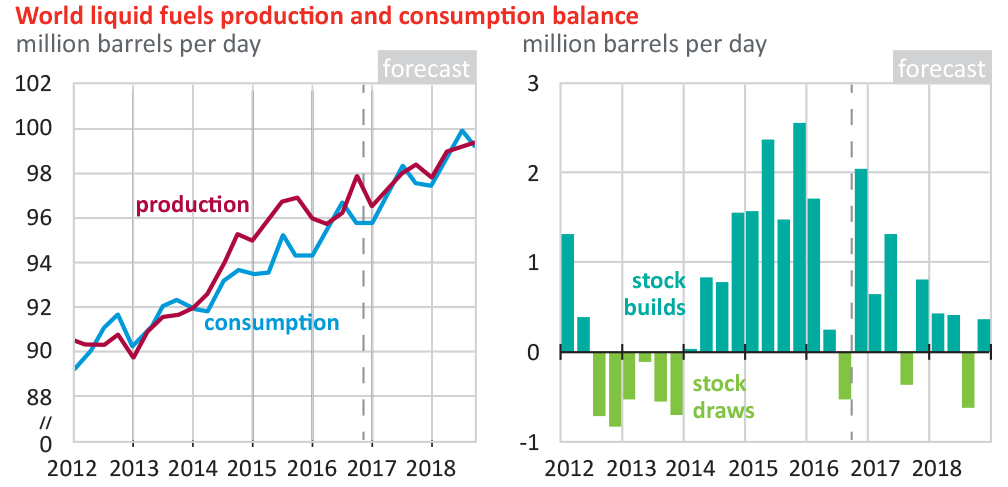

The global consumption of oil continues to rise, nearly reaching the “100 million barrels per day” mark in March 2019. However, simply commissioning new wells and rigs to capitalize on this trend is not always feasible. When new wells are possible, the integrity of the entire operation and the OCTG require precise controls and process interventions. Consequently, this ensures the maximum yield over the longest lifecycle period of production.

This is where pipe protection technologies are driving operator efficiencies by ensuring threads, connections, perforating guns, and hammer unions remain reliable during each stage of the project. Thread corrosion and mishandling of tubulars during well drilling construction can cause compromised connections. Ultimately, this leads to safety and production risks after its completion. Compromised connections in the well can reduce overall yield. It could also create unfortunate conditions that result in wellbore failures, possibly killing the well.

To reduce the risks associated with weakened threaded connections of your OCTG, MSI Pipe Protection Technologies continues to develop and manufacture new and innovative protection tools to serve the industry.

Pipe Protection for each Stage of the Project Lifecycle

MSI provides pipe handling and protection equipment for all types of oilfield operations, whether it be onshore or offshore, as well as underground mining, or water well applications. Designed with reliability in mind, the various pipe protection devices perform under extreme environmental conditions. In using MSI’s protection equipment, operations benefit from both corrosion prevention and the reduction of any damage to the threaded parts.

MSI’s state-of-the-art manufacturing facility produces the highest quality plastic and metal products to cater to any type of pipe protection requirements. When the project’s success is determined by the shortest time to production, ensuring that all onsite equipment is defect-free prior to use or installation becomes part of the critical path.

MSI’s Pipe Protection Solutions

Offering a wide variety of solutions for even more types of applications, MSI improves pipe protection during every portion of the well’s construction and completion. For unique situations and environmental conditions, MSI can produce customized protectors according to any design constraint.

How a Thread Protector is Made | CNC Lathe

Thread and Line Pipe Protectors

MSI’s range of thread protectors will ensure pipe threads and connections are not compromised. Our ultimate goal is to keep threads from sustaining damage and maintain the integrity of the pipeline. MSI’s product applications also help prevent corrosion and contamination from inside the pipes and around the threads and pipe ends. Learn more below about what our product lines include.

The MSI thread protector range includes:

-

-

- Drill Pipe Protectors are provided in both plastic and steel options

- Line Pipe Protectors for plain or beveled pipe ends

- Sucker Rod Caps and Plugs

-

Branded types of thread protectors include:

-

-

- Magnum™ and Titan™ for tubing and casing that requires heavy-duty thread protection.

- MaxX™ that is specifically designed for API 5CT Annex I compliance.

- Mega™ that provides composite plastic and steel thread protection.

- Ultra™ for premium threaded connections.

- Tector™ and Tector Plus™ for an economical thread protection solution.

-

MSI Pipe Protection Technologies also has solutions for different types of perforating gun thread protection. As the performance of perforating guns helps to determine well efficiency, ensuring the connection is stable prior to detonation can influence overall performance.

Pipe Storage and Handling Equipment

For storing various types of pipe in accordance with API RP 5C1 standards, the entire stack should remain a little over one foot off the ground at all times. Furthermore, the height of the pipe stacks should be less than 10 feet. However, when operators use our bumper rings and pipe chocks, they not only remain in compliance with API safety standards for equipment storage, but they also maintain safety standards during pipe transport. In fact, these storage tool applications are ideal for preventing shifting and direct surface contact during movement and equipment transport.

MSI provides a complete range of pipe handling, storage, and transport equipment for ensuring the pipe’s integrity. In particular, our pipe packaging frames use profiled segments and steel beams to ensure persistent separation between pipes and structural rigidity during transport.

MSI’s set of pipe protection technologies include:

-

-

- Bumper Rings for continued pipe separation

- Pipe Chocks to stabilize resting positions

- Raptor Pipe Packaging Frames provide a complete and secure bundling system

- Rhino Tubular Handling Systems for heavy-duty lifting and handling

-

Using MSI’s range of tubular protection equipment will help ensure the integrity of critical infrastructure during every stage of the operational lifecycle.

Additional Protection Solutions and Custom Applications

With the safety risks involved in mismatched hammer unions, MSI offers the most common 1502 protectors in 1”, 2”, and 3” sizes. Manufactured from HDPE (High-Density Polyethylene), the hammer union protectors offer enhanced impact resistance and come stamped with size and thread information to prevent incorrect installation. Hammer union protectors also have four notches on the pad to deal with any custom installation and handling equipment.

MSI Pipe Protection Technologies also offers pipe accessories such as lifting bails and stabbing guides. For any non-standard or unique requirements, MSI can assist by designing and manufacturing protectors that suit any industrial need. With a facility that uses the latest technologies for the manufacturing process, each device will deliver according to the required customer criteria.

Connect with MSI Pipe Protection Technologies to Protect Your Bottom Line

At MSI, we take pride in helping you deliver all day, every day. As the leader in innovative pipe protection solutions for the oil and gas industry, quality assurance is our guarantee. Also, with an ISO 9001 and 14001 certified manufacturing process and a state-of-the-art facility, only high-quality protection tools leave our production line. Overall, our clients can always rest assured when it comes to protecting their investments and having peace of mind.

To start protecting the integrity of your pipe threads and oilfield equipment, contact us at 877-276-9208. MSI Pipe Protection Technologies is a NOV Tuboscope company, and we’re always here to help meet your needs.

https://blog.wellcem.com/effective-ways-of-reducing-well-integrity-problems