The oil and gas industry relies heavily on an extensive network of pipelines to extract and process oil and natural gas. To ensure the integrity and safety of these pipelines, the use of thread protectors is crucial. Here’s why thread protection is important to the oil and gas industry.

Preventing Damage to Pipes During Transportation

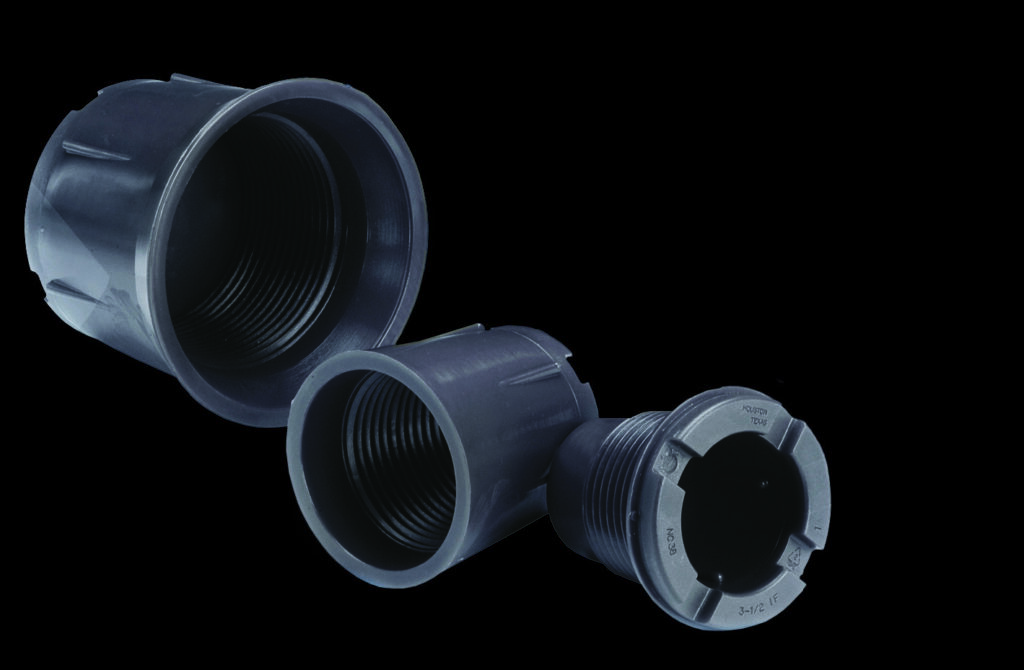

Thread protectors prevent damage to the threads of pipes. Although pipes are constructed using durable materials, threads require protection due to precise manufacturing tolerances, which ensure secure and tight seals upon assembly.

Damage to the threads before installation creates weak spots, posing significant risks like oil spills or explosions. Thread protectors offer a straightforward solution to potential problems. Thousands of pipe protectors are utilized yearly to keep pipes secure, preventing the potential for billions of dollars in damage costs.

Reducing Maintenance Costs

Although pipes are constructed from robust materials like steel and iron, they require maintenance to ensure longevity and optimal performance. Pipes are transported to construction sites and often stored outdoors, leading to rusting and corrosion. Pipe protection prevents rust and moisture accumulation.

Minimize Safety and Injury Risks

Pipes are often heavy and necessitate specialized equipment for transportation. Moreover, the threads on pipes are the sharpest part and can harm individuals and nearby machinery.

To address this, thread protectors shield the ends of pipes from damage and the individuals working nearby. Thread protectors reduce serious injuries, creating a barrier between the sharp threads and people or equipment. This precautionary measure enhances safety during handling and transportation.

What to Consider When Selecting Thread Protectors

When choosing thread protectors, it’s important to consider several factors.

Here are key considerations:

Durability

Opt for thread protectors that offer long-lasting performance under demanding conditions. Since these protectors are reusable, selecting ones that provide the longest lifespan for the cost is essential.

Compatibility

Different pipes have varying thread specifications, so matching the threads with the appropriate protector is important. Additionally, consider the diameter of the pipe, as thread protectors should fit securely and snugly. Failure to use the correct thread protector can negate the benefits of having them in the first place.

Cost-Effectiveness

Consider the relationship between the protector’s cost and its expected duration. Generally, if a thread protector is more expensive, it should offer a longer lifespan and durability.

By assessing the cost concerning the projected usage period, make an informed decision that ensures optimal value for your investment. This allows you to balance cost and longevity, selecting thread protectors that align with your budget while providing the durability to meet the intended lifespan requirements.

Ease of Use

Ease of use is of paramount importance. Choosing simple, easy-to-install and remove protectors requires minimal effort and time.

Given the many pipes involved in oil and gas projects, opting for user-friendly thread protectors significantly contributes to efficient project management.

Get The Right Thread Protectors from MSI

For assistance finding thread protectors for your specific requirements, partner with MSI. As a specialized manufacturer of thread protection systems, MSI is well-equipped to cater to your needs. With our expertise and industry-leading position, we provide top-quality thread protectors tailored to your project’s specifications.

To ensure you acquire the right thread protection solution, reach out to us at MSI. Our team will guide you through the selection process, considering compatibility, durability, cost-effectiveness, and ease of use factors.